The new forums will be named Coin Return (based on the most recent vote)! You can check on the status and timeline of the transition to the new forums here.

The Guiding Principles and New Rules document is now in effect.

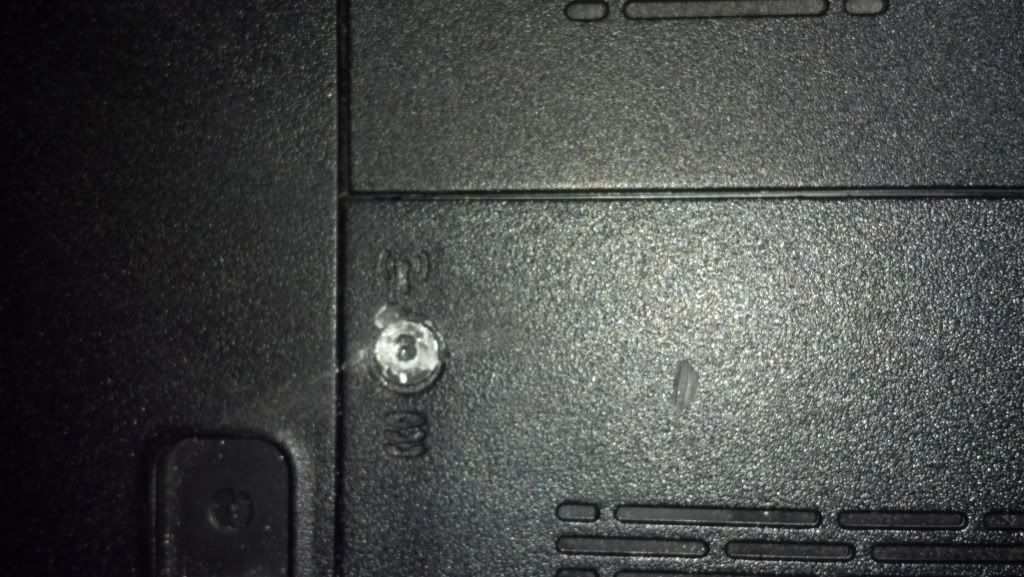

Stripped Laptop Screw

JustinSane07 Really, stupid?Brockton__BANNED USERS regular

Really, stupid?Brockton__BANNED USERS regular

Really, stupid?Brockton__BANNED USERS regular

Really, stupid?Brockton__BANNED USERS regular

So I've got a doozy of a stripped laptop screw in my old HP laptop. The screw is one of the two screws holding down the hard drive cover.

I have tried:

Super Gluing a screw driver to the screw

The Elastic Band method

Dremeling a notch to put a flathead in

I don't want to drill or hammer into the screw due to it's location and size. That might be bad.

Does anyone have any other ideas on what could get this out?

I have tried:

Super Gluing a screw driver to the screw

The Elastic Band method

Dremeling a notch to put a flathead in

I don't want to drill or hammer into the screw due to it's location and size. That might be bad.

Does anyone have any other ideas on what could get this out?

JustinSane07 on

0

Posts

1: break or cut the plastic carefully and than try to glue it back

2: go get yourself a screw extractor for smal screws, any local hardware store will carry a selection, just get ones sized to your screw.

next time don't try and dremel the screw, and get the screw extractor sooner, they work really well and won't damage anything but the screw your pulling out.

I'll have to go home depot tomorrow and get a small screw extractor kit.

but screw extractors aren't a bad thing to have around for the future anyway, Phillips head screws get stripped way too easily.

Phillips head screws are designed to strip easily, whether that's a good thing or not.

No, they're not. http://en.wikipedia.org/wiki/Henry_F._Phillips

I thought it was also a safety feature, as slotted screws tend to have the blade slip out.

http://en.wikipedia.org/wiki/List_of_screw_drives#Phillips

"the Phillips screw drive was purposely designed to cam out when the screw stalled, to prevent the fastener damaging the work or the head, instead damaging the driver. This was caused by the relative difficulty in building torque limiting into the early drivers."

I dunno who wrote that Wikipedia article, but it needs some [citation needed] inserted into it. The Philips head screw was designed for use with automatic drivers, because slotted screws do not self-center on the driving bit, as Phillips do. The fact that Phillips head screws 'cam out' if you apply too high a torque to them is a bug, not an intended feature. It is also why the Reed and Prince and Superdrive screw bits exist...

Anyhow, I'm sure one thing we can all agree on is that Torx is the superior fastener driving system.

fixed that for you. but seriously Torx is good too. and the screws on the laptop were probably Pozidriv, but people generally don't own Pozidriv screwdrivers and phillips screwdrivers fit into them, it just increases the chance of a stripped screw.

Supposedly they are supposed to resist cam out, but the taper on the sides makes it almost as bad as Phillips. When are we just going to velcro/ziptie everything together, all the time?

Yes, zipties will clamp down a cylinder head very nicely. No, don't argue.

What is the model of your laptop and how old is it?

You're gonna have to do some rigging to keep the screwdriver upright while the JB Weld sets.